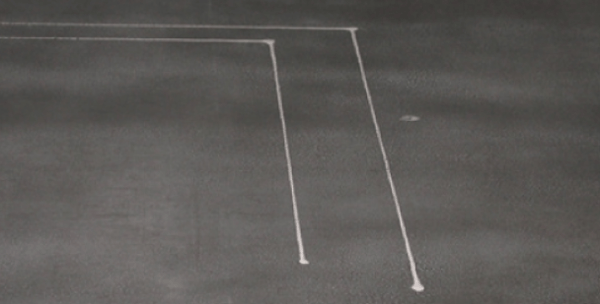

After each demoulding cycle, the moulds are cleaned and set for dimension using plotter paint, accurately placed by a high Tech machine called a “Plotter”. This process is to ensure that the end result meets the precise required dimensions required by the end user.

Deviations in the dimensions of concrete elements are expensive as the elements are all bespoke to the particular contract but can also result in a logistical nightmare when rescheduling any elements that are to be remade, then we have the burning question “What do we do with the elements that are wrong” ?

In this blog I will try to explain more about plotter paint and the problems that may arise from plotter paint and I will give you an insight into the benefits of the plotter paint supplied by Ecoratio.

What is plotter paint?

A good quality plotter paint accurately highlights the individual footprint of an element whilst identifying bespoke service points critically important to the service life of the element. A good quality plotter paint will give you sharp, fine lines with millimetre precision without spreading ensuring dimensional accuracy.

Problems with plotter paint during the concrete production

There are several problems that can be caused by the use of plotter paint:

- Deviating dimensions

- Corrosion on the mould

Some types of plotter paint can cause corrosion to the mould surface. Moulds with corrosion have a reduced lifespan as a result of the “pitting” from the degradation effect from the corrosion process, this will also affect the surface quality of the concrete elements with corrosion staining mirrored from the mould to the element surface. This mirrored staining can be costly in terms of time and materials to repair and could result in delivery delays while the repairs are completed.

- Blocking of nozzles and feed lines

Poor quality plotter paint can have consequences for the plotter machine. When poor quality plotter paint dries in the tip, it creates blockages in the system therefore stopping the whole production process, which is expensive. In addition, low or poor quality plotter paint may not be pure enough resulting in contamination by larger or coarse particles in the plotter paint, resulting in blocked nozzles and feed lines, again bringing the production process to a grinding, expensive halt.

Why choose Ecoratio’s plotter paint

At Ecoratio the plotter paint is produced to the highest standard to ensure dimensional clarity and accuracy, reducing waste and expensive delays in production.

Advantages of Ecoratio's plotter paint:

- Our plotter paint will have no visual effect to the surface of your concrete elements.

- All Ecoratio products are both user safe and environmentally friendly;

- Our plotter paint will not cause corrosion due to the addition of advanced an anti-corrosion agents;

- Due to the composition of our plotter paint, the nozzles or feed lines will remain clear and from blockages;

- Our plotter paint does not dry out and contains no coarse particles that causes clogging.

If you would like more information about any of our environmentally friendly products at Ecoratio, please check our eBook "Products and Services" you will find an overview of all products and services that support your needs and the needs of the concrete industry as a whole.