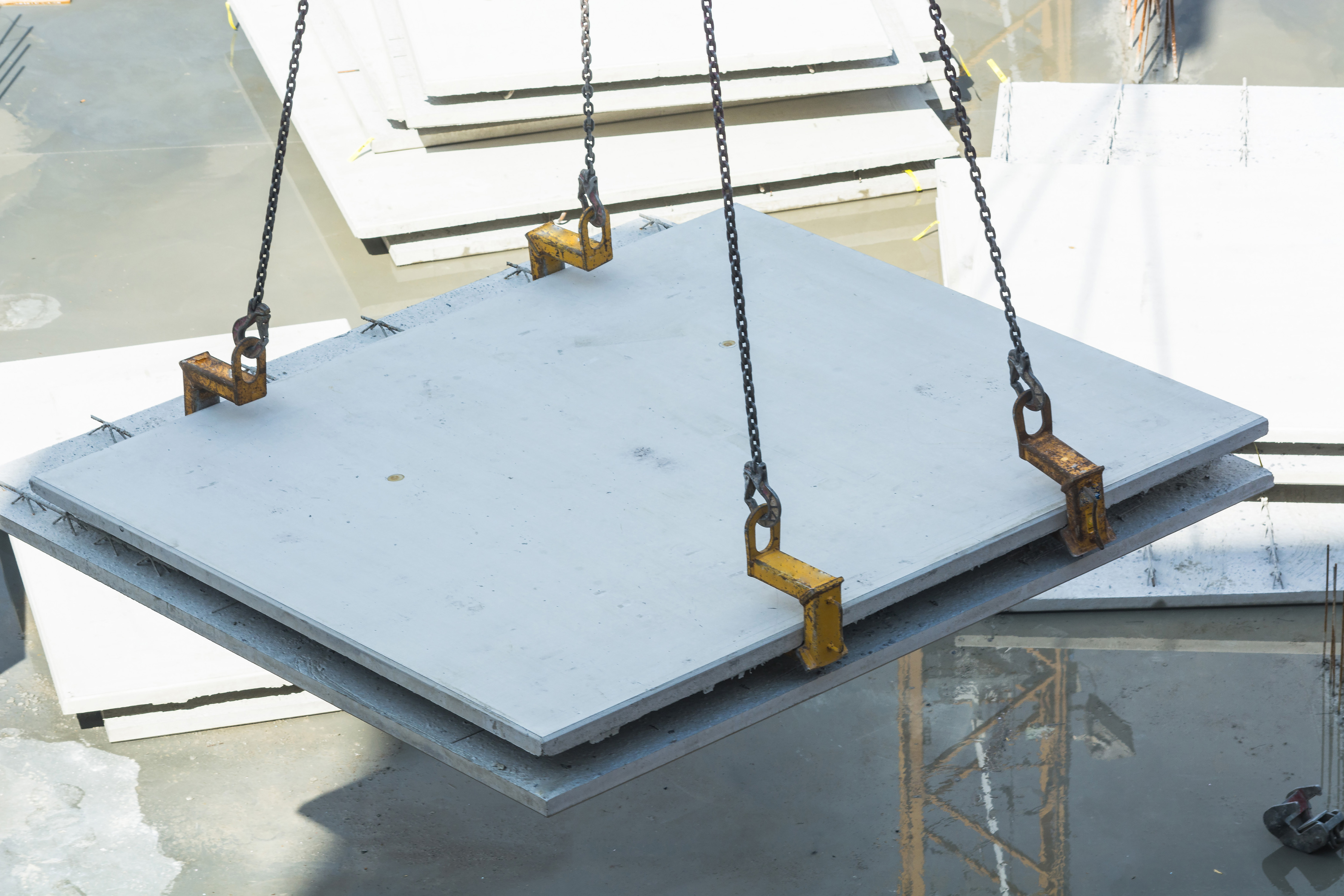

Precast concrete panels are produced hundreds of times every day around the world. There are many different purposes for the precast concrete panels and there are differences in size, function and costs. They have one thing in common: the need for high-quality concrete and finishing. How this can be achieved is explained in this blog.

At Ecoratio we help our customers achieve high quality concrete panels and other precast concrete elements. During the production process of the concrete elements, problems may occur that affect the overall quality of the concrete. There are various potential surface issues that can affect the quality and durability of the precast element. In our experience the following problems regularly occur with precast concrete panels:

Surface voids

Surface voids are created by air trapped against the surface of the mould or form. For every one percent of entrapped air within the concrete section the overall structural strength is reduced by 5 percent. Surface voids often arise due to a few potential causes, incorrect application of concrete release agent, poor concrete placement and/or concrete consolidation practices, You can read how you can solve this problem in this article.

Concrete dusting

Excessive surface dust occurs regularly within the precast industry. If the dust is not removed from the surface of the mould during the cleaning/preparation process it will react within the hydration process creating a hardened build-up, this hardened build-up will reduce the quality of the mould and dimensional accuracy of the element that is cast within the mould. In this blog we give you various tips to prevent concrete dust.

Concrete discolouration

Concrete discolouration is the discoloration of the concrete surface from stains. The discolouration could be the result of one or more of the following potential causes, the incorrect use of materials, the excessive use of water, the use of calcium chloride and the excessive application of concrete release agents in the precast concrete forms. To prevent concrete discolouration in the future, we have prepared some tips.

High quality precast concrete

There are various problems that occur during any pre-cast concrete production process. In addition to the above problems, you may also be confronted with:

To gain insight into all possible solutions in the production of your precast concrete elements, we have the following eBook available for you, a manual that takes you to high-quality concrete. This eBook can be downloaded free of charge and without obligation: